Dedicated to supporting Builders Merchants

In over 30 years we have been trading we have refined and added to our product offering to ensure we stay at the cutting edge of the market in terms of quality and price.

Highest Quality Products

Technical Advice

Innovation

National Distributors

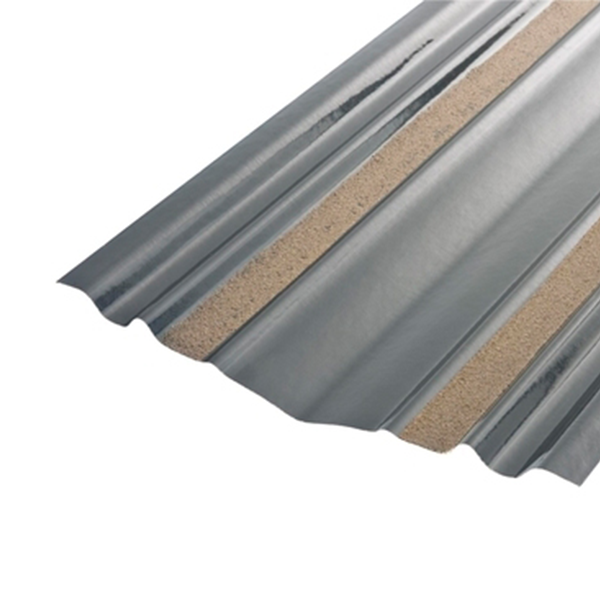

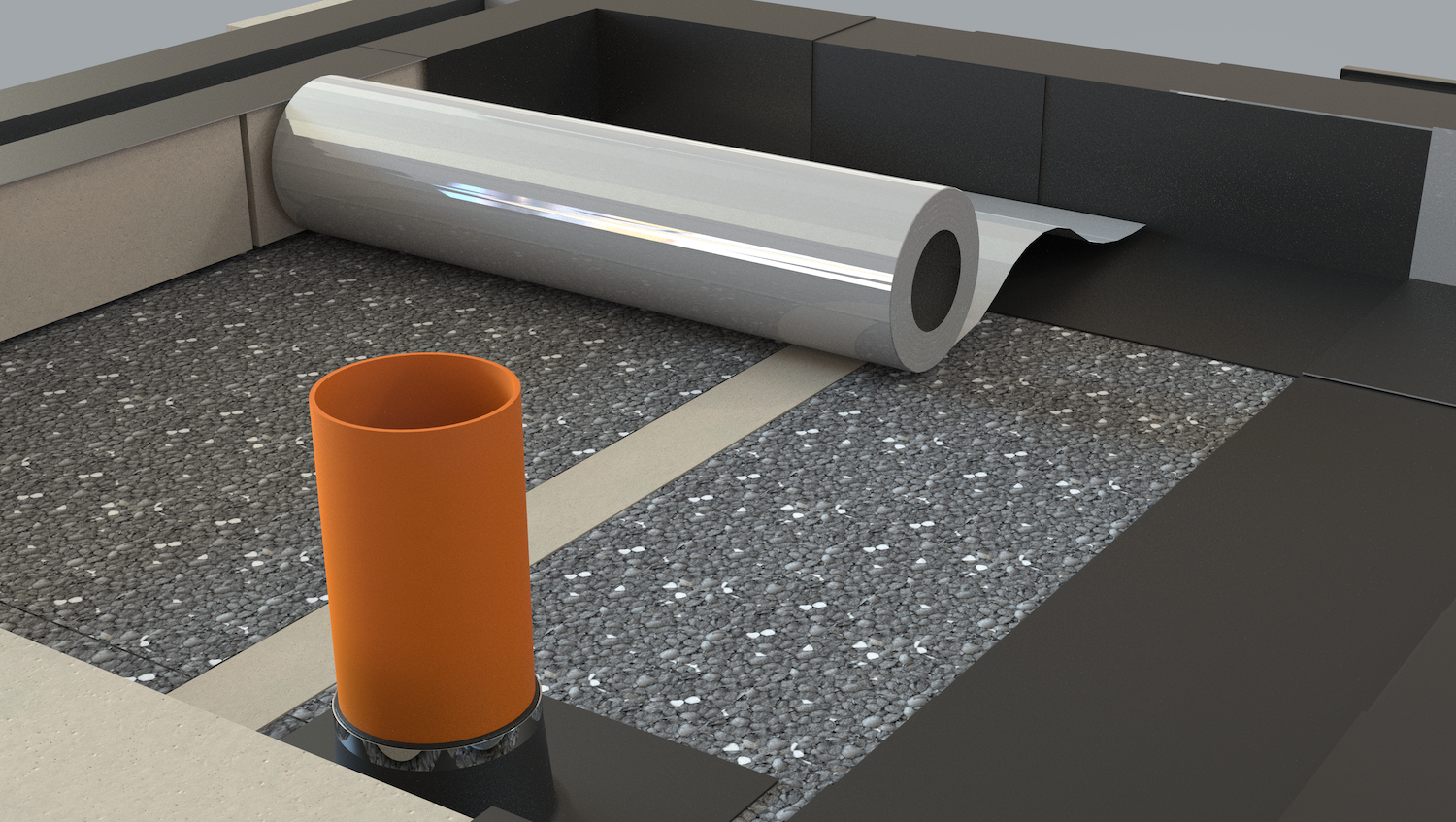

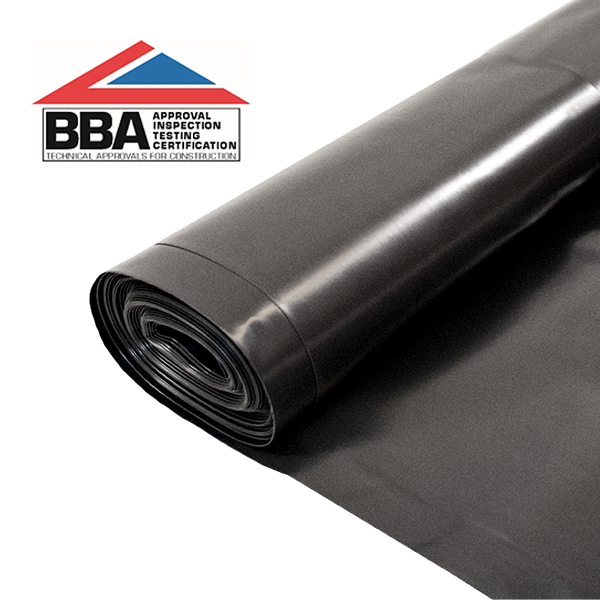

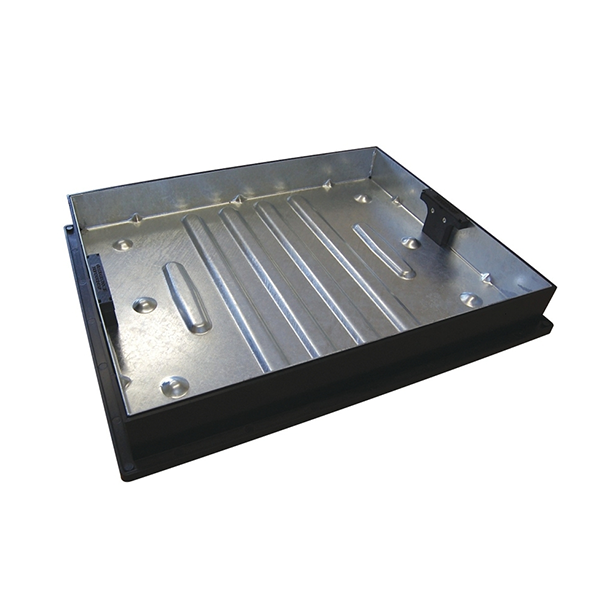

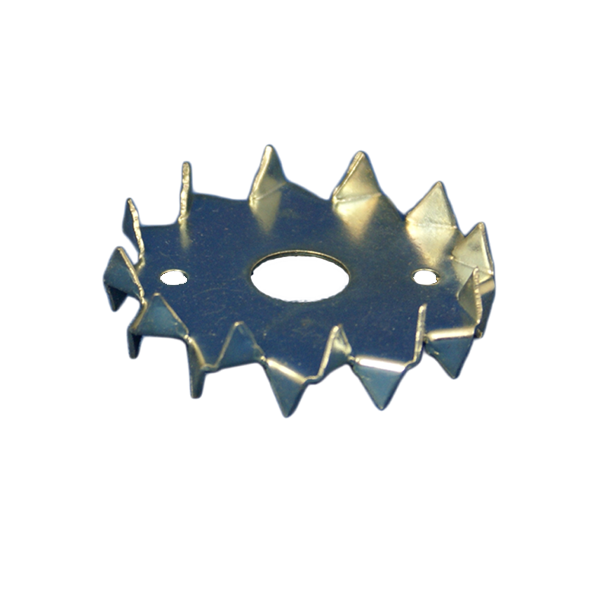

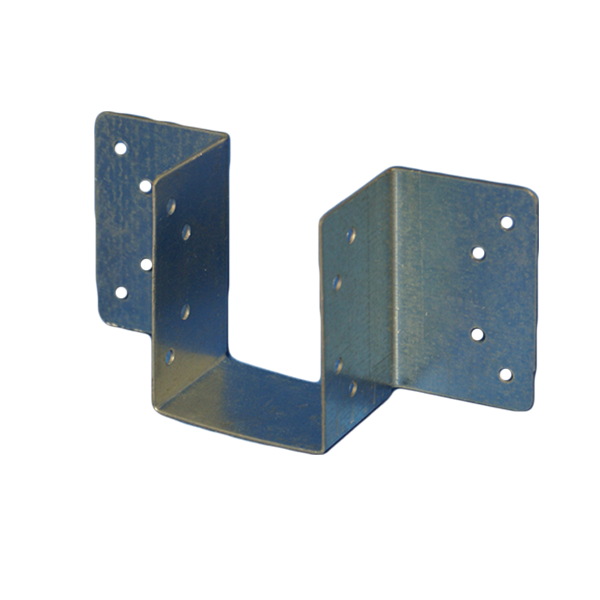

Our Product Range

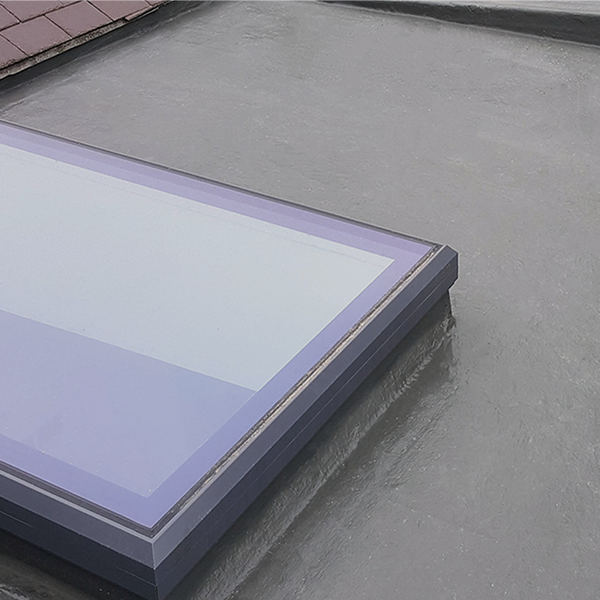

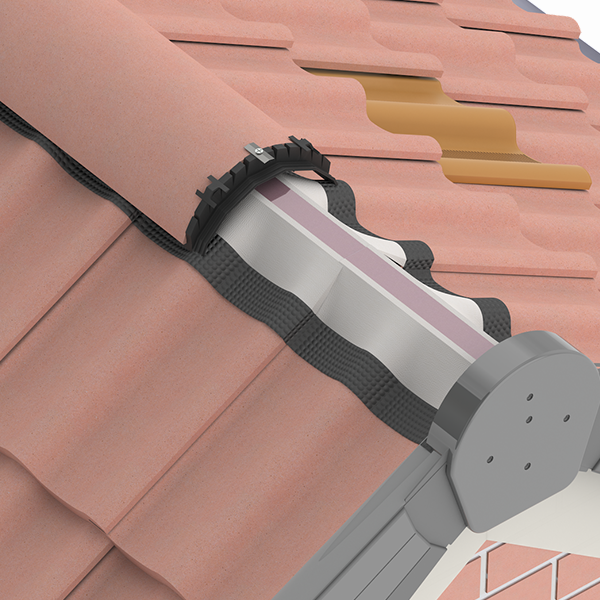

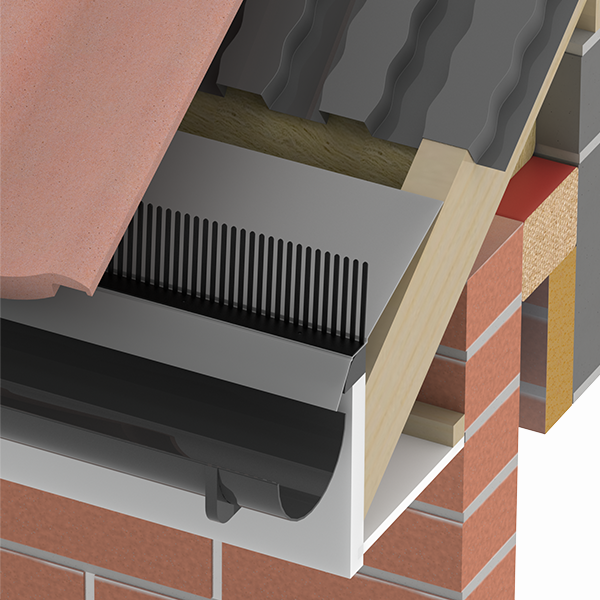

- Roofing

- Groundwork

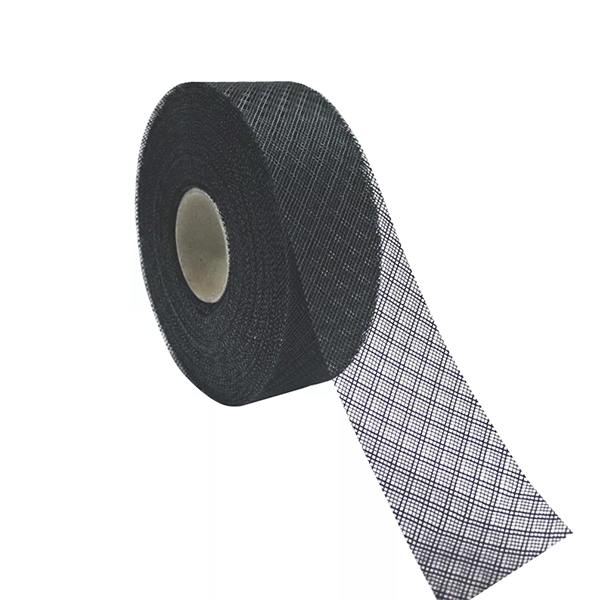

- Weed Control & Geotextiles

- Plastering

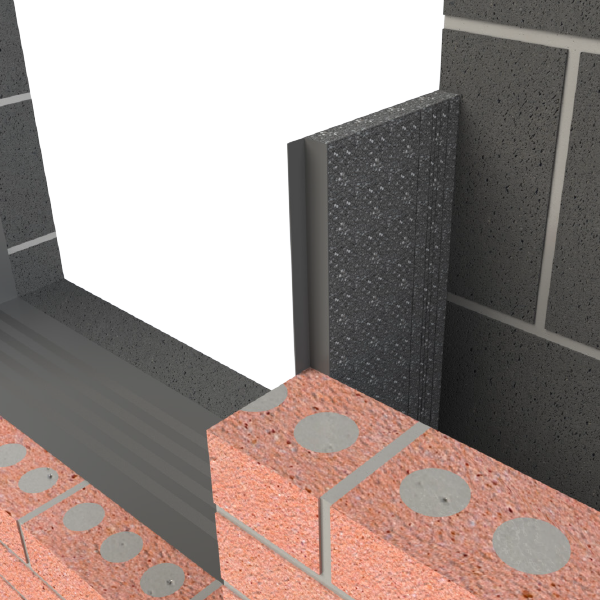

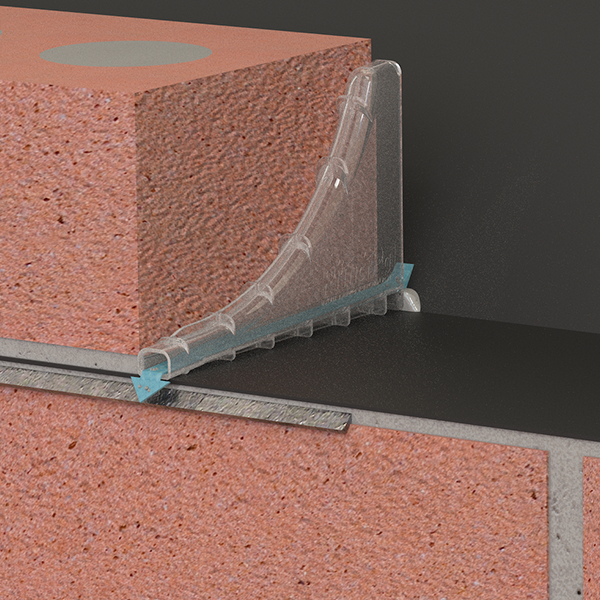

- Brickwork

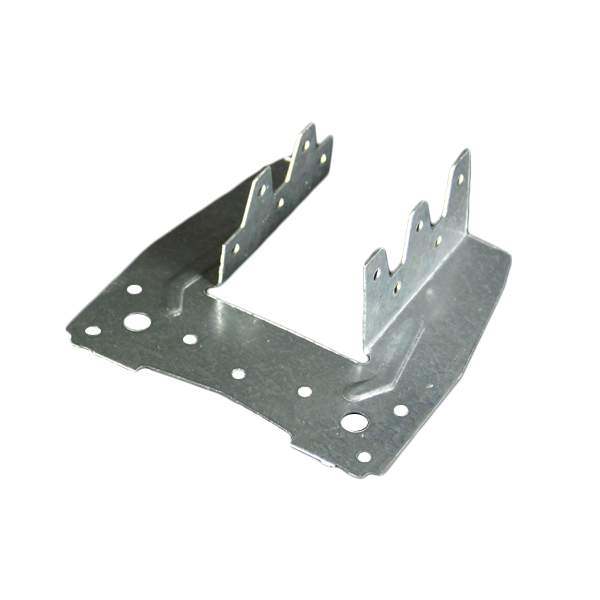

- Fixings

- Ventilation

- Ancillaries

Over 30 Years of Service

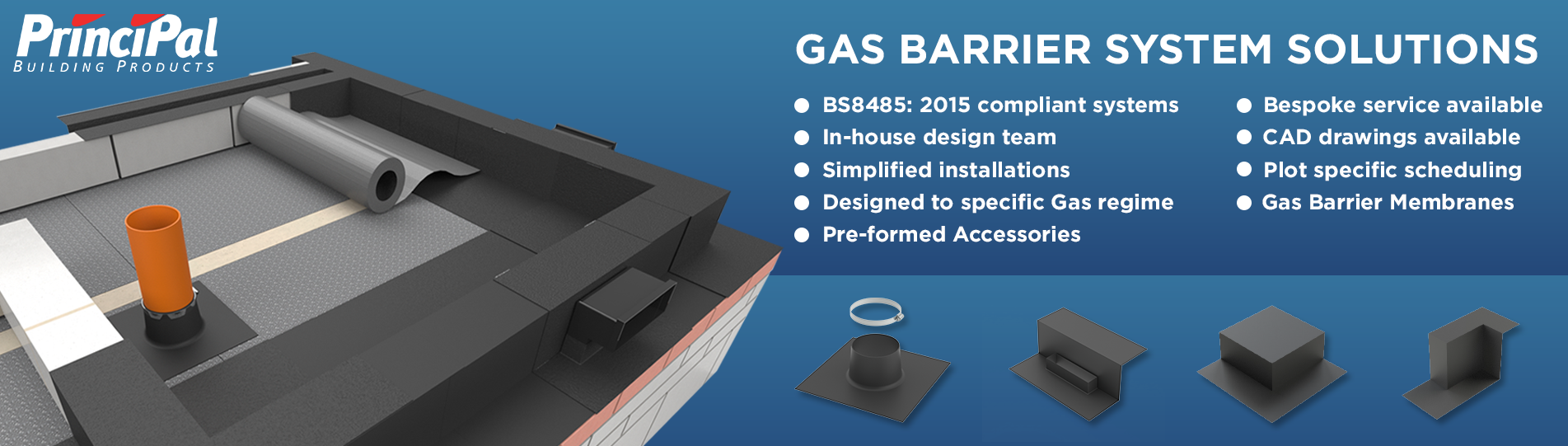

Principal Building Products has become a respected and substantial supplier of quality construction products to Builders Merchants throughout the UK. We deliver and supply products that are both manufactured to our strict specifications and supplied from third parties. We have a wide range of product categories for building products, including but not limited to housebuilding and construction products that include roofing, plastering, fixings, ventilation, groundwork, brickwork drainage and weed control geotextile products.

In the thirty years we have been trading we have refined and added to our product offering to ensure we stay at the cutting edge of the market in terms of quality and price. Now trading from our facility in Rotherham, the company offers a huge range of products and remains committed to supplying the market only via bona fide Merchants.

We still believe people prefer to deal with people so our staff members are knowledgeable and helpful, with the technical expertise to ensure our customers can rely on us. We will deliver the right product – on time! Where required we can deliver next day anywhere in the UK. Still proud to be in family ownership, the company will always maintain its customer focused philosophy and pride itself on delivering real value.

Product Resources

All our product data sheets are available to download. D.O.P's and C.E documentation can be sent on request. We regularly update our literature with changes in industry regulations.

Contact Us

For all enquiries please contact

- 01709 728150

- sales@pbptld.co.uk